|

Thomason Machine Works, Inc. bought our first CNC Machining Center in 1989.

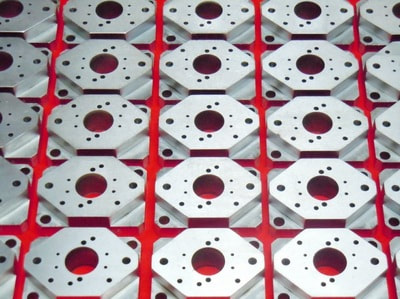

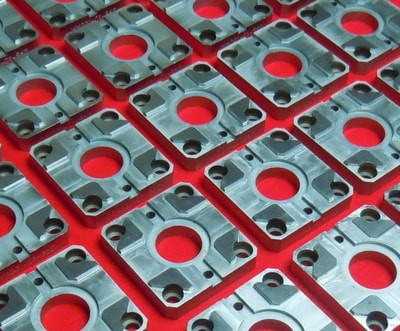

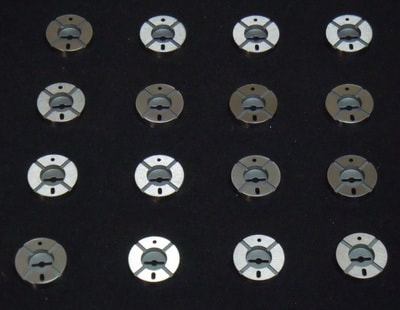

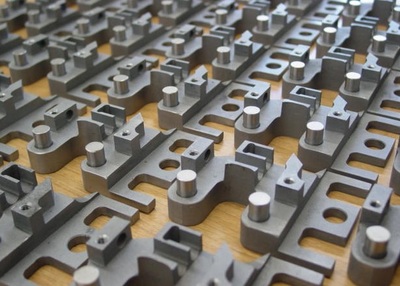

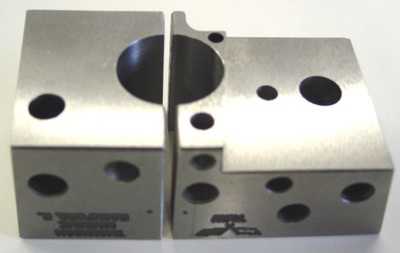

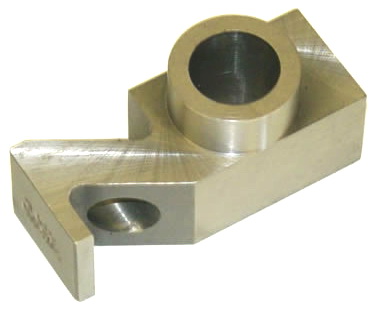

That's over 30 years of CNC Machining experience! Our state-of-the-art equipment grants us the flexibility to handle complex designs with a variety of materials. Materials include ferrous and non-ferrous metals, plastic and more. Industries such as medical and aerospace require parts with close tolerances, and it is our promise here at Thomason Machine to work with our customers to make sure their designs are fabricated with uniformity and a quick turnaround time, all at a competitive price. We currently have over 10 CNC Machining Centers and are constantly upgrading to the newest technology. Thomason Machine Works, Inc. can supply you with just one unique part all the way to production machining of up to 10,000 pieces, we are ready to do a job of any size for our customers. |

|

CNC Milling History

Numerical control (NC) refers to the automation of machine tools that are operated by abstractly programmed commands encoded on a storage medium, as opposed to controlled manually via hand wheels or levers, or mechanically automated via cams alone. The first NC machines were built in the 1940s and 1950s, based on existing tools that were modified with motors that moved the controls to follow points fed into the system on punched tape. These early servomechanisms were rapidly augmented with analog and digital computers, creating the modern computer numerical control (CNC) machine tools that have revolutionized the machining processes.

In modern CNC systems, end-to-end component design is highly automated using computer-aided design (CAD) and computer-aided manufacturing (CAM) programs. The programs produce a computer file that is interpreted to extract the commands needed to operate a particular machine via a postprocessor, and then loaded into the CNC machines for production. Since any particular component might require the use of a number of different tools-drills, saws, etc., modern machines often combine multiple tools into a single "cell". In other cases, a number of different machines are used with an external controller and human or robotic operators that move the component from machine to machine. In either case, the complex series of steps needed to produce any part is highly automated and produces a part that closely matches the original CAD design.

In modern CNC systems, end-to-end component design is highly automated using computer-aided design (CAD) and computer-aided manufacturing (CAM) programs. The programs produce a computer file that is interpreted to extract the commands needed to operate a particular machine via a postprocessor, and then loaded into the CNC machines for production. Since any particular component might require the use of a number of different tools-drills, saws, etc., modern machines often combine multiple tools into a single "cell". In other cases, a number of different machines are used with an external controller and human or robotic operators that move the component from machine to machine. In either case, the complex series of steps needed to produce any part is highly automated and produces a part that closely matches the original CAD design.