|

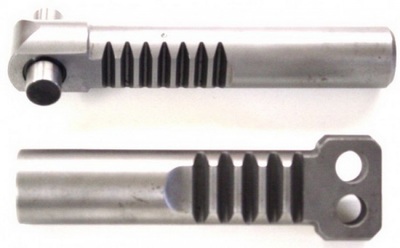

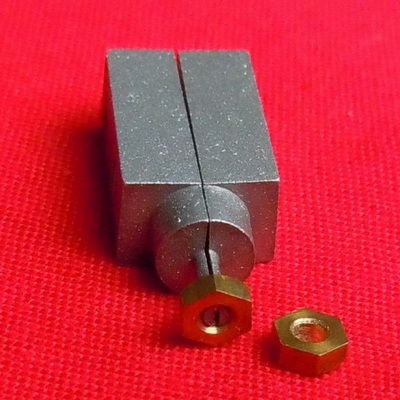

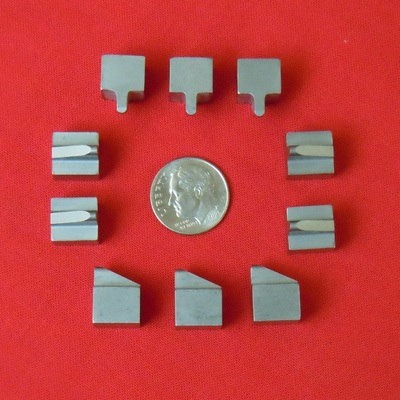

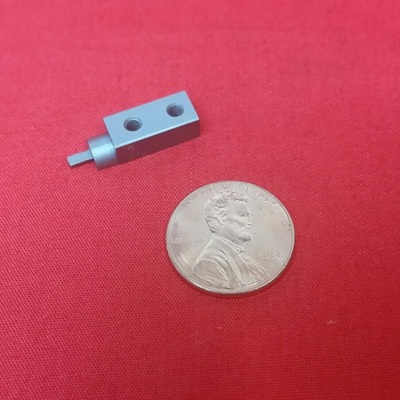

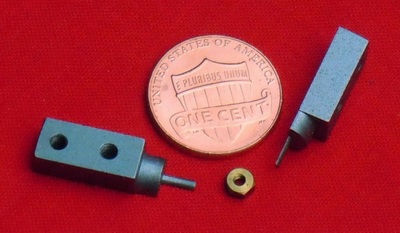

Thomason Machine Works, Inc. has the ability to manufacture our replacement parts to precise specifications using one of our 3 Charmilles Robofil 310 wire EDM"s which are capable of cutting 15 inches tall and up to 30 degrees of taper. Our electrical discharge machining (EDM) allows us to work with hard to machine materials and complex shapes that are difficult to obtain with traditional processes. Along with electrode machining, we also perform sinker electrodischarge machining, making us a one stop shop that can complete a part while assuring quality and quick turnaround.

We continually manufacture not only parts for the Fastener Industry but also for aerospace, medical, robotics and energy markets. |

By using EDM machining we are able to manufacture parts from multiple materials including: Brass, Tool Steel, Carbide, Aluminum, Graphite and other exotic metals. We have the capacity to supply your production needs from prototype work and short runs to medium or long run production.

Thomason Machine has been manufacturing repair and replacement parts for header and roll thread machines for over 40 years. We have a 37,000 square foot facility with new machines and the best machinists. At TMW we do not only serve Northern Illinois and Southern Wisconsin, but we also serve many national and international customers.

Contact us or fill out the RFQ Form for any of your wire and conventional EDM needs.

Thomason Machine has been manufacturing repair and replacement parts for header and roll thread machines for over 40 years. We have a 37,000 square foot facility with new machines and the best machinists. At TMW we do not only serve Northern Illinois and Southern Wisconsin, but we also serve many national and international customers.

Contact us or fill out the RFQ Form for any of your wire and conventional EDM needs.